Did you know that ICAM Virtual Machine allows for Material Removal Simulation and 3D Measurement?

Did you know that ICAM Virtual Machine allows for Material Removal Simulation and 3D Measurement?

ICAM Virtual Machine (VM) features Material Removal Simulation (MRS) to simulate the cutting action of the tool with respect to stock definitions and to perform collision checking between collision-enabled components and the in-process stock.

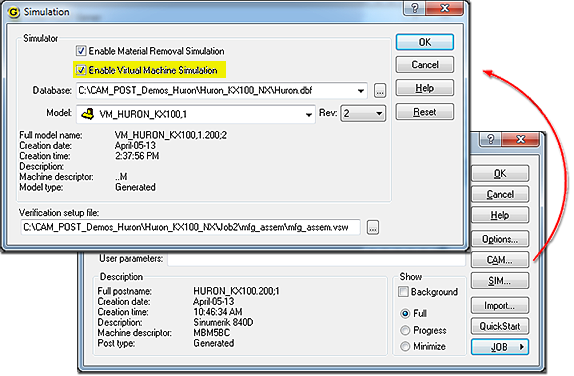

MRS can be enabled from the main panel of the CERUN and GENER launch facilities using the [SIM…] button. Selecting this button raises a “Simulation” dialog that can be used to enable the MRS:

MRS is licensed option of VM. If the MRS license is not available, the MRS check box cannot be selected.

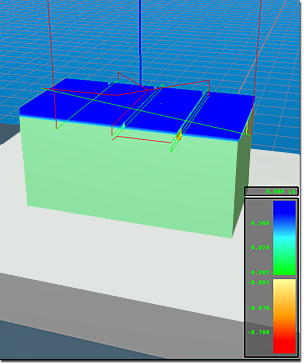

When running VM with MRS (material removal simulation) active, 3D measurement features will be available to view: the in-process stock; Boolean over-cut and under-cut stock (i.e., gouge and excess material); a color graduated Boolean difference between part and stock; and a cross section cut-out of the stock.

The left-most of the circled buttons above toggles the display of the in-process stock. The two buttons to its immediate right toggle the display of the Boolean over cut (gouge) and Boolean undercut (excess) material. The gouge and excess calculations are done using an exact comparison between in-process stock and its associated part.

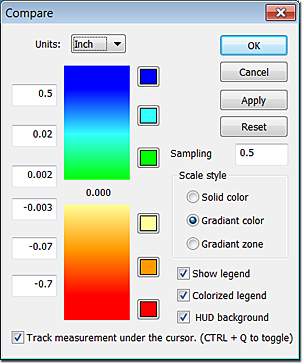

The Boolean excess and over-cut results can sometime be misleading, since it can be difficult to judge the thickness of the excess or gouge material. VM provides a color graduated part/stock comparison feature to address this issue.

Benefit to User

With material removal simulation (MRS) programmers can compare the in-process stock against the original part to display gouges and excess material and they can check collision between collision enabled components and the In-process stock.

For more information or comments, please do not hesitate to contact Phil at TechTipTuesday@icam.com