Categories

Workpiece compensation (e.g., G54, G55…) adjusts the axes of the CNC machine to account for the difference in workpiece origin between the as programmed origin in the CAM system and the as-setup origin at the CNC machine. Workpiece compensation provides the CNC operator flexibility in part setup, in much the same way as tool compensation provides flexibility in tool setup.

So, how do you pass the workpiece compensation requirements from the CAM system, to the post-processor, and from there, on to the CNC machine?

One method is to use a post-processor command to tell the CNC which workpiece compensation offset to use. For example:

CUTCOM/ON,ADJUST,offset

CAM-POST is a generic post-processing system, so requesting offset 2 might generate a G55 on one machine, a G54.1P2 on another and an E02 on a third. A common mistake is to use the value 55 for offset, which in all likelihood would generate a diagnostic.

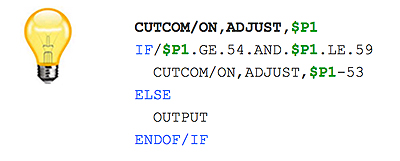

However, if you have a CAM-POST Developer’s license, you can easily create a CUTCOM user-defined macro so that the post-processor can recognize and support offset numbers specified as machine G codes. For example:

Many CAM systems provide menus, dialogs or other interfaces to specify workpiece compensation. For example, CATIA’s Auxiliary Operations dialog has a “Machining Axis Change” button, which can be used to specify workpiece compensation.

Follow these steps to insert a workpiece compensation change into your manufacturing process:

1. First select a manufacturing operation in the PPR tree. The workpiece compensation change will be added after the selected element in the manufacturing process.

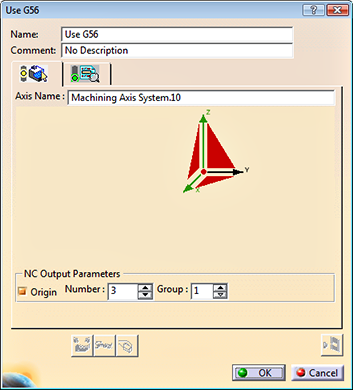

2. Next, select the Machining Axis Change button ![]() in the Auxiliary Operations toolbar. The Machining Axis Selection dialog box will appear allowing you to define the origin and orientation of the workpiece. If the “Origin” check-box is selected (as shown below), then CATIA will also output a workpiece compensation change post-processor command with the specified offset number (CAM-POST ignores the Group setting).

in the Auxiliary Operations toolbar. The Machining Axis Selection dialog box will appear allowing you to define the origin and orientation of the workpiece. If the “Origin” check-box is selected (as shown below), then CATIA will also output a workpiece compensation change post-processor command with the specified offset number (CAM-POST ignores the Group setting).

3. You can optionally give a more meaningful name to the axis change operation so that you can better recognize it when later viewed in the PPR tree.

Benefit to User

Workpiece compensation simplifies the setup of the part at the CNC machine.

For more information or comments, please do not hesitate to contact Phil at TechTipTuesday@icam.com