Categories

February 12, 2012

Valley Machine Shop Inc. (VMS), located in Kent, Washington, manufactures small to large aerospace details and assemblies and has specialized in CNC Milling and Turning applications for over 30 years. VMS uses mainly Mastercam X6 for its part programming, employs 60 people and operates twenty 3-5 Axis Mill & Lathe CNC machines.

VMS is a growing company that is constantly investing in new machines and software technologies to better serve its clients and to remain competitive in the marketplace.

According to Jerry Gustafson, NC Programmer at VMS, outsourcing NC manufacturing software was a tedious and time consuming task until ICAM Technologies’ advanced NC post-processing and G-code verification products were investigated and implemented within its manufacturing environment.

Finding a Mastercam post-processor was a slow and frustrating process…

On the contrary, ICAM collected information about VMS’ 5-Axis SNK milling machine equipped with a Fanuc controller from day one. ICAM knew the correct questions to ask and the result was a nearly working post-processor when the machine was installed on the shop floor.

“Working out any post issues was quick since we worked directly with ICAM’s post engineers, who responded quickly with changes, or explanations,” said Jerry Gustafson. “ICAM’s engineers are very knowledgeable and helpful and the sales representative that managed our account contacted us regularly to make sure we were satisfied with the post. I look forward to work with ICAM on new projects the future.”

VMS Upgrades to ICAM’s Integrated PSE…

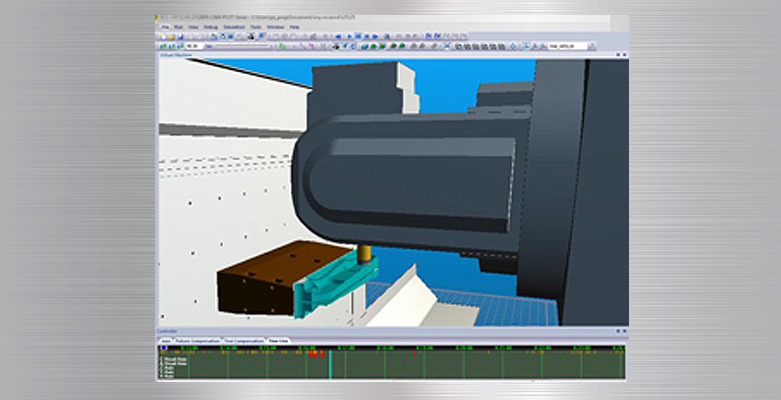

Building on the productivity gains obtained from implementing ICAM’s post-processing solution into its production facility, VMS has upgraded to ICAM’s Integrated PSE solution that provides the means for post-processing, simulation and G-code verification inside a single software platform. VMS can now compute in-process stock geometry to identify, list and display surface gouges, excess material, inaccessible areas and rapid-motion collisions at any time during the post-processing and verification phase.

About ICAM Technologies Corporation

For over 40 years ICAM Technologies has been specializing in the development of advanced NC post-processing solutions using its CAM-POST® technology, for manufacturers in major industries around the world. ICAM has added an integrated machine tool simulator, Virtual Machine®, with the provision for G-code machine simulation driven by ICAM Control EmulatorTM to its product mix that further strengthened its position in the NC manufacturing market. ICAM customers benefit from dramatic improvements to CNC machine optimization, NC programmer productivity and manufacturing process efficiency. ICAM’s unique technology and services provide its customers and industry partners with the competitive edge that their business operations and customers demand.

Contact Information

ICAM Technologies Corporation

Phil Masella

Marketing Communications Manager

phil@icam.com