Categories

The typical process of fine-tuning a post-processor consists in running the post iteratively on one or more cutter location files, then analyzing the results and making the changes required.

During this process, it is sometimes necessary to stop and postpone the fine-tuning for later. In such a case, it is preferable to have the ability to resume the analysis at the exact place in the program where it was stopped, rather than to restart the entire job from the beginning, which could be time consuming.

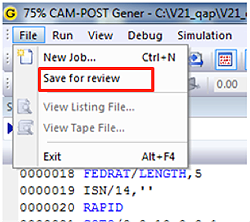

The V21 full interface of GENER and CeRUN offers a new function called Save for review, which saves the current state of the process for later review. This option is available in the File menu.

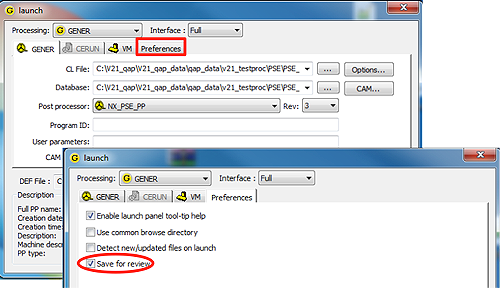

In the Preferences tab of both GENER and CeRUN, a new Save for review option is also available. If this option is checked, GENER and CeRUN will automatically save their current status any time the process is stopped.

Either one of these options will save all necessary data into a compressed archive with the extension ZRJ.

To review a job previously saved for review, simply drag and drop the ZRJ file onto the launch panel or desktop icon (or alternately open it from the

[Job] button). The launch panel will automatically change the type of Processing to REVIEW and will activate the Full interface.

The interface will then show the status of the job at the moment GENER or CeRUN was stopped. This includes:

- Input, Output (GENER only) and Console window complete traces

- Source window listing the input file

- Diagnostic window listing all diagnostics

- Virtual Machine simulation window

- Controller window including TimeLine access to entire program

- Material removal simulation window

- View listing and view NC code menu selections

Benefit to User.

Save time and increase efficiency during the process of fine-tuning a post.

For more information or comments, please do not hesitate to contact us at TechTipTuesday@icam.com