Categories

Sometimes a machine rotary axis has a small range on one side and a bigger range on the other side.

Let us take an example of a milling machine using an “A” rotary on the head and a “B” rotary axis on the table. The “A” axis range would be -110 to +45 degrees and the “B” axis range would be -360 to +360 degrees.

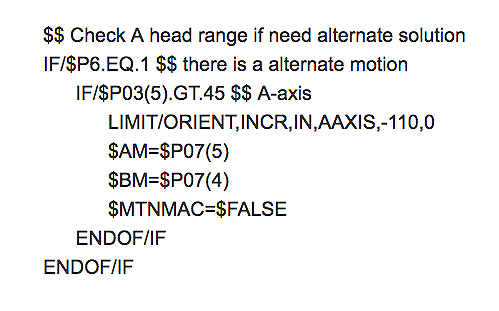

In case you want to avoid possible overtravel on the smaller range side of the “A” axis, you can write a macro in “Motion startup macro” to force the rotary axis to use the alternate kinematic solution. See the example below for an “A” head rotary axis ranging from -110 to +45 degrees and a “B” table rotary axis ranging from -360 to +360 degrees.

Benefit to User.

Create a post to support a better rotary solution.

For more information or comments, please do not hesitate to contact Phil at TechTipTuesday@icam.com