Did you know that CAM-POST has a new feature called “SmartCUT” that eliminates “air cutting” motions?

SmartCUTTM uses material removal simulation to identify motions programmed to run at cutting feedrates while the tool is not engaged in material. These motions, commonly referred to as “air cutting”, are wasting precious machining time and can significantly reduce overall productivity. Whenever possible, SmartCUT will change these time-wasting motions to RAPID or high-feed positioning.

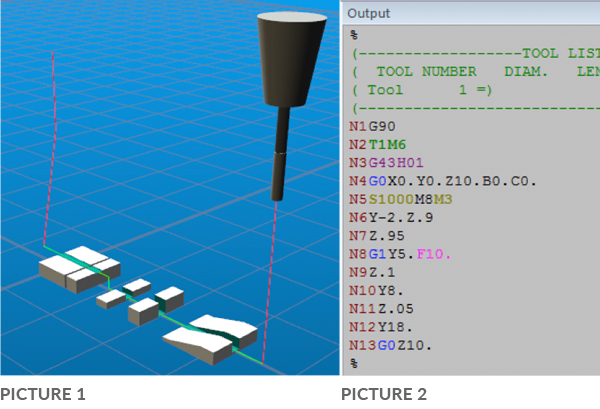

In the example illustrated in PICTURE 1, the tool is taking a single pass while alternating between cutting and not cutting modes. Red lines represent rapid moves and green lines are cutting feedrate motions. Note that in several places, green lines are passing through air at cutting feedrate, unnecessarily increasing the total machining time.

PICTURE 2 shows the generated NC code when running the post-processor without SmartCUT.

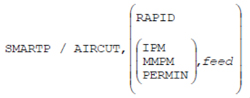

o activate the SmartCUT feature, the following command must be inserted in the Cutter Location data:

- SMARTP / AIRCUT, ON

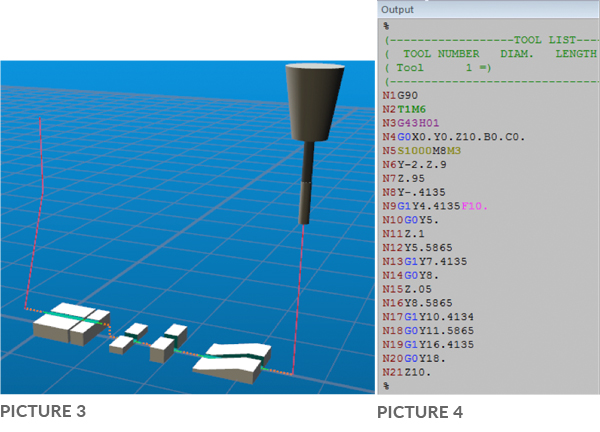

PICTURE 3 shows the tool path produced when the post-processor is executed with the SmartCUT feature activated.

PICTURE 4 shows the generated NC code. Notice that additional RAPID motions were generated wherever the tool was not engaged in material.

SmartCUT can use either high feed or rapid positioning when replacing air-cutting motions with positioning ones.

SmartCUT goes one step further, by detecting RAPID or high-feed motions that cut into the in-process stock and (in addition to warning the NC programmer) automatically reducing the feed rate to the upcoming programmed feed to avoid tool breakage. Similarly, when leaving the material, SmartCUT detects RAPID motions that cut the stock when leaving the part, and automatically slow down these cutting moves to the last programmed feed.

SmartCUT also provides a series of filters to ignore air cutting moves shorter than a specified length; to enforce a minimum safe distance on air cutting moves and to define the minimum safe positioning approach and feed distances.

Benefit to User

Increase machining productivity by eliminating unnecessary air cutting feedrate motions.

For more information or comments, please do not hesitate to contact Phil at TechTipTuesday@icam.com