Categories

One of the common shortcomings of trunnion-table 5-axes milling centers (i.e. machines with two rotary tables) is that most post-processors will output rotary positions that orient the workpiece opposite to the operator. This is extremely inconvenient, especially when running the program for the first time, as operators have no way to visualize the machining process.

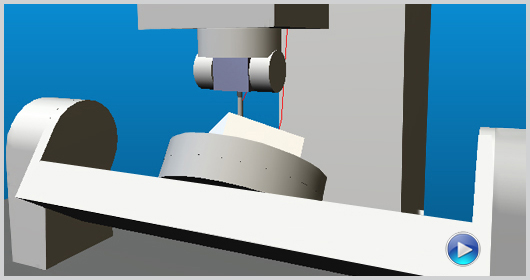

Table Opposite Operator

This “behavior” is quite common to most post-processor systems and is due to the fact that any post will compute rotary orientations using the closest path (the solution which results in the least amount of motion). Sometimes the resulting rotary orientation is facing the operator, some other times it isn’t.

Most trunnion-table operators eventually get used to this nuisance, but they decidedly prefer programs where the work is always in sight over programs where it is not.

With CAM-POST, the solution is simple: the post can be instructed to “prefer” a certain rotary travel range (the one facing the operator), on all 5-axes positioning moves.

This can be done by simply inserting a custom command in the Cutter Location Data file. Depending on the CAM system, this can be achieved using different methods.

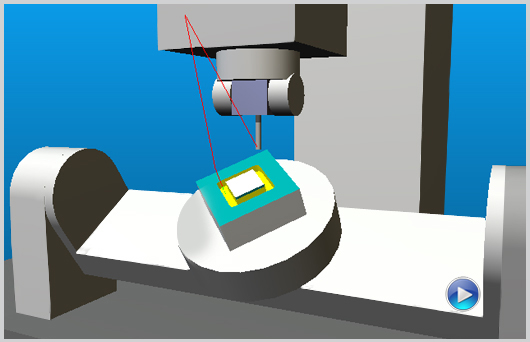

Table Facing Operator

The CL command:

Let’s take, for instance, an “A-C” trunnion-table mill (i.e. “C” rotary mounted on top of “A” table), as illustrated above. Let us assume that the “A” table can travel between -90 and +90 degrees. The “preferred” orientation, where the part is quite visible to the operator, would therefore be something like -90 to +20 degrees.

The following command:

LIMIT / ORIENT, INCR, AAXIS, TABLE, -90, 20

inserted at the beginning of the process will influence the subsequent choice of rotary solutions from the two possible solutions normally available for any tool orientation. This action would only affect non-linearized rapid positioning moves.

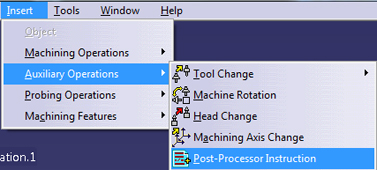

In CATIA, you can insert the LIMIT command documented above using a Post-processor Instruction.

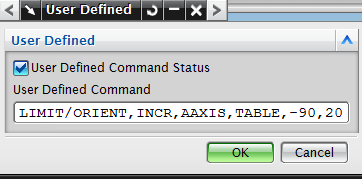

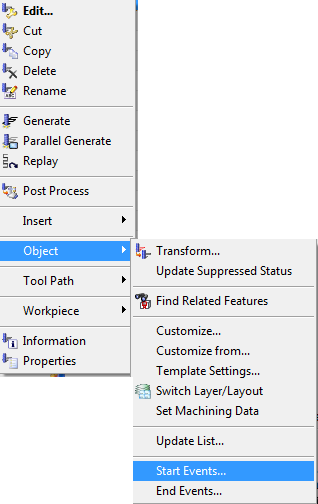

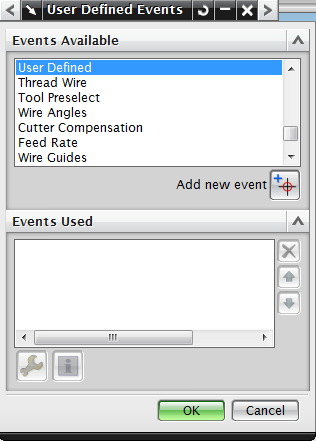

In Siemens-NX, this command can be inserted using a User-Defined Event. Select the User Defined UDE on the pull-down list and type the LIMIT command in the field.

Benefit to User

With this CAM-POST automatic “prefer” feature, programmers can easily modify their program to reposition the table to face the operator; thereby, allowing him/her to visualize the cutting process.

For more information or comments, please do not hesitate to contact Phil at TechTipTuesday@icam.com