Categories

On mill-turn machines equipped with a B-axis head, it is now possible to generate turning toolpaths where in addition to the X- and Z-axes, the B head can be used to control the turning tool orientation. This type of turning can improve the chip load and optimize the use of cutter nose radius compensation.

The turning tool can be positioned at the desired orientation by inserting a MOVETO or a CLAMP command in the part program. Depending on the CAM system, this can be done using a PP Instruction (CATIA), a Manual Entry (Mastercam), a User-defined Event (NX CAM), a Custom CL command (Creo NC), etc. Alternately, if the CAM system allows, the tool orientation can be programmed with a continuously-changing tool axis vector, in which case the post will generate toolpaths where X, Z and B move simultaneously.

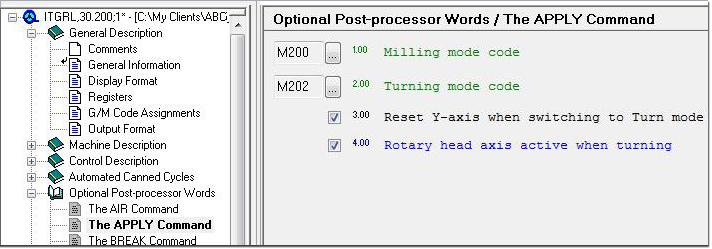

To enable this feature in the Questionnaire, go to the “Optional post-processor words” section, select the word APPLY and check question #4.00.

Benefit to User

Allow the control of the tool axis orientation during turning operations on mill-turn machines.

For more information or comments, please do not hesitate to contact Phil at TechTipTuesday@icam.com