Categories

Does the following scenario sound familiar? You spent hours programming a part for a particular machine in your shop. You posted the toolpaths, verified and simulated each operation and got everything ready for machining. But just as you’re about to load your program, you realize that the machine is not available – either because of maintenance schedules, or simply because it is running another job…

There is, however, another machine available, but it is a completely different machine, with different kinematics, different travel limits and even a different control brand.

What are your options? You have a post configured for this other machine, but first you’ll have to reprogram the job in order to take into account the new kinematics and travel envelope. You will then have to post and verify each operation, which might require several iterations. You’re literally “back to square 1”. Delivery deadlines notwithstanding, the machine would also have to remain idle for a few more hours until you finish reprogramming.

What if all you would have to do would be to simply post your existing data with the post-processor configured for the new machine and let the post handle the new kinematics, travel limits and, of course, the specifics of the new control? And if the program envelope is too large for the new machine, the post would find solutions by automatically activating other axes, even though this action has not been programmed in the CAM system? Your new program would be ready to run in just a few minutes. Now this would be a time saver, wouldn’t it?

Let’s take for example a simple 3-axes job, originally programmed for a 3-axes VMC, which now has to run on a 5-axes horizontal boring mill.

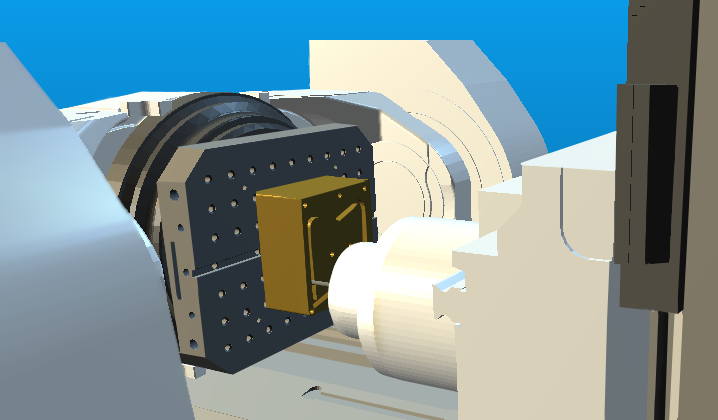

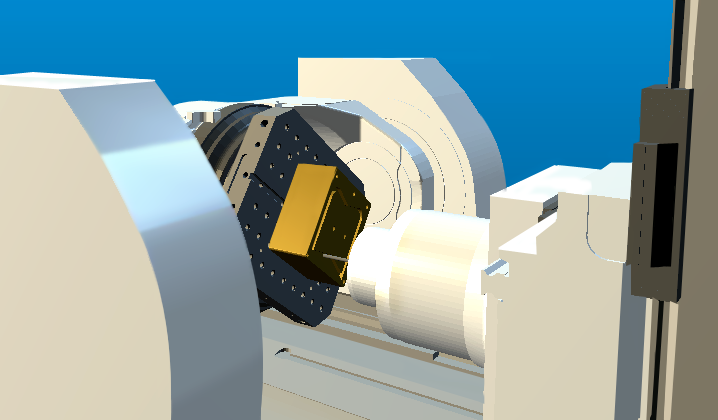

Due to the lower travel limit of the Y-axis of the new machine, the original program would normally cause an over-travel error. The lowest Y-axis position attainable on the machine is illustrated below.

However, the new post is configured to automatically switch from Cartesian to polar coordinates whenever the minimum Y-axis travel limit is attained. As a result, the post automatically issues a series of linearized A-axis motions to complete the programmed toolpaths without running into over-travel errors.

If the user prefers to control this option manually rather than have the post default to this behavior, a special CL command can be inserted in the CAD/CAM system using the method specific to each software (i.e. PP Instructions in CATIA, “INSERT” User-Defined Events in UG-NX, Custom CL Commands in Pro/NC, Manual Entries in Mastercam, etc.). For the particular example illustrated above, this special command would be: LIMIT / POLAR, YAXIS, min_Y_limit, LARGE, SCAN, ON (where min_Y_limit represents the actual value of the minimum travel limit of the Y-axis).

Benefit to User

Avoid reprogramming for another machine when kinematics and/or travel limits are different.

For more information or comments, please do not hesitate to contact Phil at TechTipTuesday@icam.com